In the process of cement production, the stable operation of the ball mill is very important. According to statistics, the transmission system failure accounts for about 82% of the main problems of the ball mill, of which the main bearing failure accounts for about 20%. In view of this, this paper puts forward the following suggestions for the maintenance of the main bearing of the ball mill:

More >

After 3 to 5 years of use of the motor, its bearings may be damaged. Therefore, in the overhaul, inspection and maintenance of bearings is an essential step.

More >

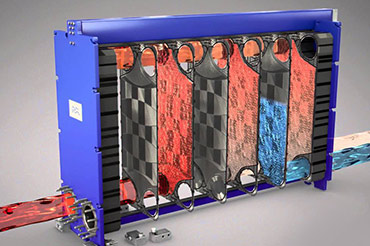

Plate heat exchangers are widely used in modern industry, especially in the power industry, because of their efficient heat exchange performance, compact structure and easy maintenance. However, when applied to critical systems such as lubricating oil cooling, small deformation can cause instantaneous fluctuations in lubricating oil pressure, which can affect the safe operation of the equipment.

More >

As the core component of rolling mill, the life of rolling mill bearing directly affects the operating cost and efficiency of the equipment. This paper discusses the main factors affecting the life of rolling mill bearing, and puts forward the corresponding improvement measures to extend the service life of the bearing.

More >

When the grease in the rolling mill bearing dries out and hardens due to a variety of factors, the friction between the mechanical components will be intensified, resulting in a rise in temperature and further accelerating the aging of the grease. This not only affects the performance of the device, but can also cause serious failures. This paper analyzes the main causes of grease drying, and provides ways to prevent and solve this problem.

More >

The steel ball is the core component of the rolling bearing, and its performance directly affects the life and running stability of the bearing. This paper describes the processing technology of steel ball, including material selection, processing technology and equipment, and quality control methods, and discusses how to improve the quality and durability of steel ball.

More >

Plain bearings play a vital role in mechanical vehicles, and their damage can lead to a series of problems, such as wear, heat and even bite death. This article focuses on how to prevent these injuries through proper assembly and maintenance, proper use, and regular inspection to ensure efficient bearing operation.

More >

The life of a rolling bearing refers to the time or number of turns experienced from the beginning of use until fatigue spalling occurs. This paper discusses the main factors affecting bearing life reliability, emphasizes the importance of correct installation, maintenance and lubrication, and points out the common problems leading to early failure.

More >

If you have any questions about the product, or have special needs, we want our experts to give your solution, please click here.

Contact Us

We can deliver to all countries

Tel:+86-13485059519

WhatsApp/WeChat:+86-13485059519

E-mail:tbjbearing@gmail.com

24 Hours Online

Scan, contact customer service